The Extensive Applications of Tungsten Needles in Industry

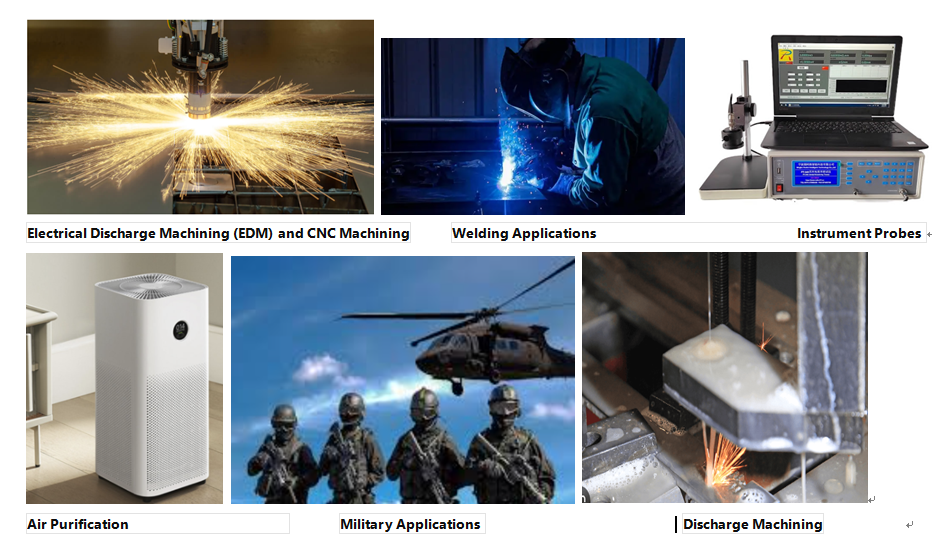

Tungsten needles composed of refractory alloys are ultra-vertical electrodes widely used in different industrial fields. Excellent electrical conductivity and high temperature resistance make them an indispensable functional material in modern industry. Tungsten needles are widely used in EDM and CNC computer machining. They can accurately process various metal materials such as carbon steel, stainless steel, silicon copper, copper, bronze and titanium.

The high hardness and wear resistance of tungsten needles enable them to withstand high temperatures and pressures, ensuring machining accuracy and efficiency. Tungsten needles play an important role in welding, especially in tungsten inert gas welding. During the welding process, an arc is formed between the tungsten electrode and the workpiece, and the filler metal is injected into the welding pool formed by the arc heat. Tungsten electrodes, due to their high melting point and temperature resistance, can prevent melting and burning, making them suitable for welding thin plates (up to 4mm) such as pipes and tube-to-tube sheet connections.

Instrument probes Sharp tungsten needles are mainly used as instrument probes. For example, in digital quaternary detectors, the resistivity and sheet resistance (sheet resistance) of semiconductor materials are measured. The fine tip of the tungsten needle ensures precise contact with the test material, obtains accurate measurement data, and improves the accuracy and reliability of the test. EDM tungsten needles are also used in EDM processes. During the EDM process, both the workpiece and the electrode (tungsten needle) are immersed in a dielectric fluid, and a high-voltage pulse generates sparks between the workpiece and the electrode, causing local melting and evaporation of the workpiece surface to achieve processing.

The tungsten needle has a high melting point and temperature resistance, which ensures its stability and durability in EDM. In the air purification system, the tungsten needle is used as a discharge electrode. By applying high voltage to the tungsten needle, a corona discharge is generated to charge the particles in the air so that these particles can be collected and the air can be purified.

The high temperature resistance and corrosion resistance of the tungsten needle ensure their stability and life during the discharge process. Tungsten needles have important applications in the military field. Historically, tungsten was used in weapons in the era of cold weapons. For example, Chinese archaeologists found tungsten elements in the "swords" excavated. "During World War I, German arms engineers attached great importance to tungsten barrels. Data at the time showed that Russian and French light machine guns could fire about 6,000 rounds of bullets before use, while German light machine guns, using tungsten, could fire up to 15,000 rounds of bullets, more than doubling their performance. Tungsten's high hardness and wear resistance make it widely used in military equipment. In short, tungsten needles have special physical and chemical properties and are widely used in various industrial fields. They are an indispensable functional material in modern industry. With the advancement of technology, German arms engineers attached great importance to tungsten barrels. Data at the time showed that Russian and French light machine guns can fire about 6,000 rounds of bullets before use, while German light machine guns, using tungsten, can fire up to 15,000 rounds of bullets, more than doubling their performance. Tungsten's high hardness and wear resistance make it widely used in military equipment. In short, tungsten needles have special physical and chemical properties and are widely used in various industrial fields. They are indispensable functional materials in modern industry. With the advancement of technology, German arms engineers attach great importance to tungsten-containing barrels. Data at the time showed that Russian and French light machine guns could fire about 6,000 rounds of bullets before use, while German light machine guns, using tungsten, could fire up to 15,000 rounds of bullets, more than doubling their performance. Tungsten's high hardness and wear resistance make it widely used in military equipment. In short, tungsten needles have special physical and chemical properties and are widely used in various industrial fields. They are indispensable functional materials in modern industry. With the advancement of technology, tungsten needles have special physical and chemical properties and are widely used in various industrial fields. They are indispensable functional materials in modern industry. With the advancement of technology, it is possible to fire 15,000 rounds of bullets, which will more than double its performance. The high hardness and wear resistance of tungsten make it widely used in military equipment. In short, tungsten needles have special physical and chemical properties and are widely used in various industrial fields. They are indispensable functional materials in modern industry. With the advancement of technology.

In conclusion, tungsten needles, with their exceptional physical and chemical properties, have extensive applications across various industrial fields. They are an indispensable functional material in modern industry. With technological advancements, the applications of tungsten needles in industry are expected to become even more widespread and profound.