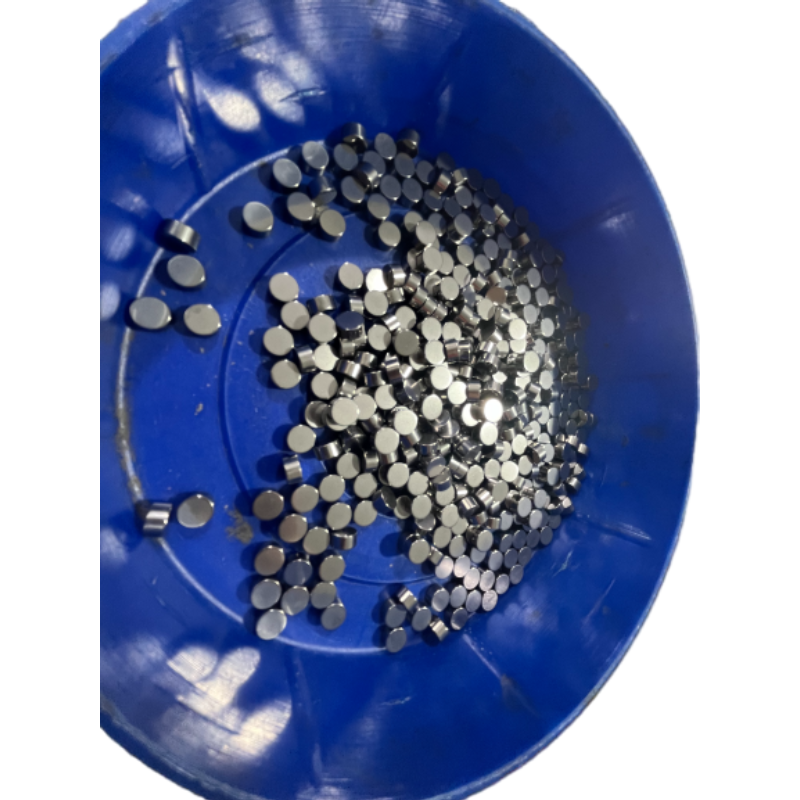

Copper-tungsten contacts play a crucial role in circuit breakers, and their functions can be summarized as follows:

1.Arc Resistance

Copper-tungsten contacts exhibit excellent arc resistance, allowing them to withstand the high temperatures and energy associated with the electrical arcs generated during the opening and closing of circuit breakers. This characteristic ensures that the contacts do not wear out or burn quickly during frequent operations, thereby extending the lifespan of the circuit breaker.

2. Electrical and Thermal Conductivity

The copper-tungsten alloy combines the high melting point and hardness of tungsten with the excellent electrical and thermal conductivity of copper. This allows copper-tungsten contacts to effectively conduct current under high-load conditions while rapidly dissipating heat, preventing overheating.

3. Wear Resistance and Anti-Burning Properties

Copper-tungsten contacts demonstrate good anti-burning capabilities, effectively resisting material loss caused by electrical arcing. Additionally, their wear resistance helps maintain stable contact performance during repeated operations.

4. Mechanical Strength and Thermal Stability

Copper-tungsten contacts possess high mechanical strength and good thermal shock resistance, enabling them to maintain structural stability under extreme temperature variations. This is critical for ensuring the reliability of circuit breakers in various operating environments.

5. Versatility

Due to their exceptional physical and chemical properties, copper-tungsten contacts are suitable for various types of circuit breakers, including SF6 circuit breakers and vacuum circuit breakers. These applications require materials that can withstand high temperatures while maintaining low gas content to ensure safety and reliability.In summary, copper-tungsten contacts are essential components in circuit breakers, providing unique properties that ensure the safe, reliable, and efficient operation of electrical devices.