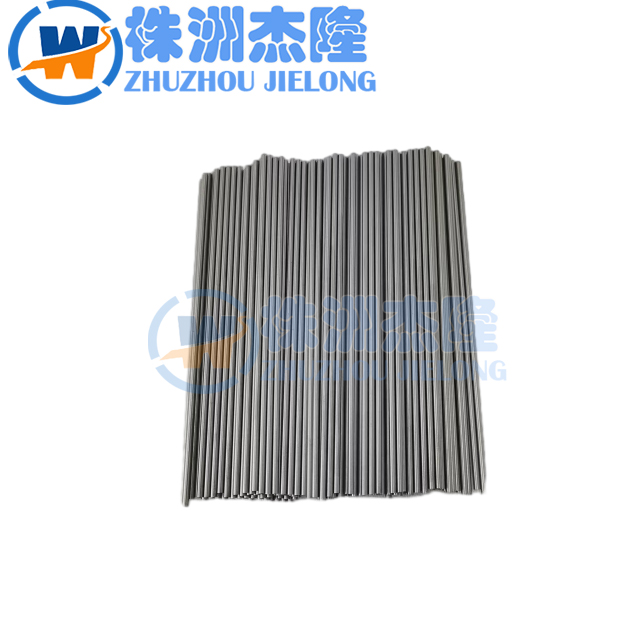

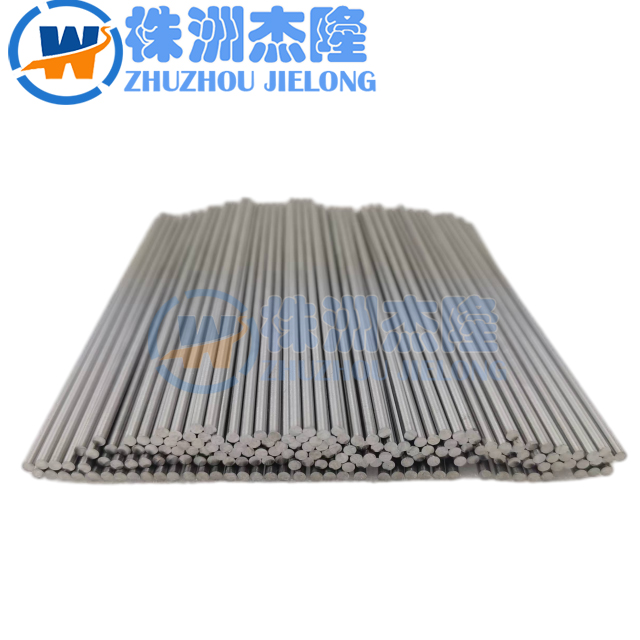

Tungsten rods are versatile components widely utilized across industries due to their remarkable properties, including an exceptionally high melting point (over 3,400°C), resistance to wear, and robust structural integrity. Here’s a more detailed look at their applications:

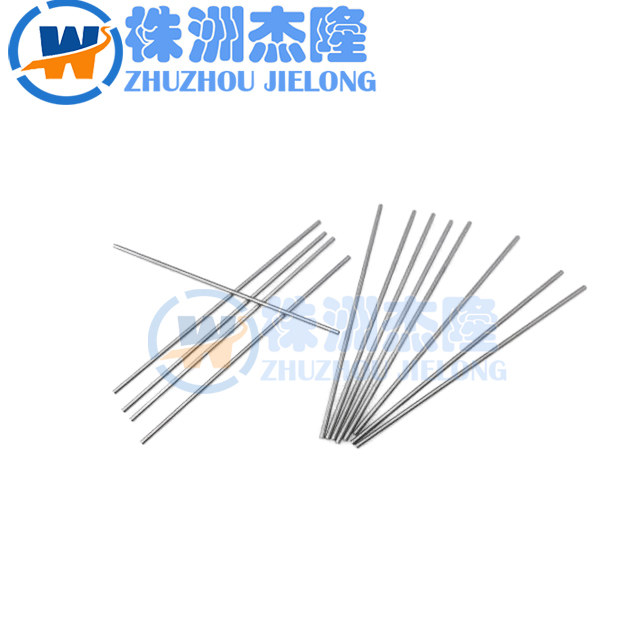

High-Temperature Environments: Tungsten rods serve as essential components in extreme heat applications, such as in furnaces for metal and glass production, where they act as heating elements that can endure prolonged exposure to intense temperatures without melting or deforming. Their heat resilience also makes them invaluable in producing electrical contacts and filaments for lighting and heating devices.

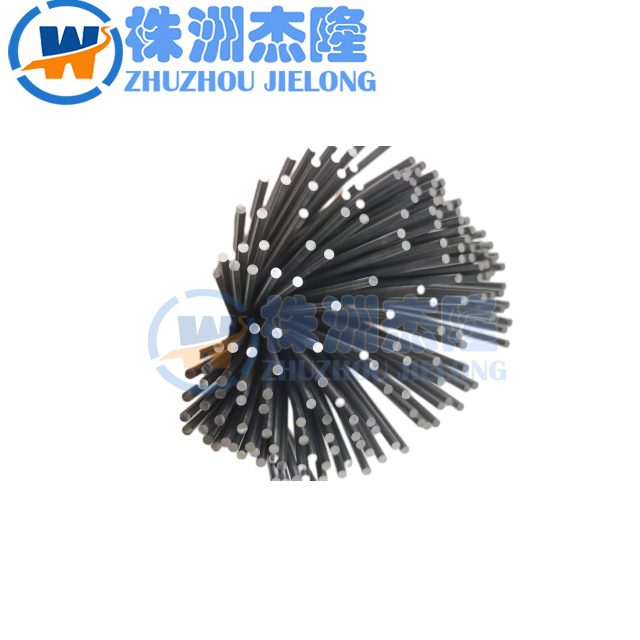

Welding and Electrodes: In welding, tungsten rods are critical in TIG (Tungsten Inert Gas) welding, as their high melting point enables them to maintain a stable arc during the welding process, resulting in precise, high-quality welds. They are commonly used in welding applications for stainless steel, aluminum, and exotic metals, providing the reliability and control needed in fields like aerospace, automotive, and structural engineering.

Medical Equipment: Tungsten rods, particularly tungsten alloy rods, are used in the medical industry to produce devices and tools such as electrodes, probes, and even radiation shields. Their biocompatibility and ability to withstand repeated sterilization make them well-suited for delicate medical equipment and surgical devices.

Electronics and Semiconductors: Tungsten’s conductive and thermal stability characteristics are vital in electronics and semiconductor production. Tungsten rods are used in the creation of contact points, electronic switches, and microcircuits due to their reliability in carrying current without deteriorating under stress.

Defense and Aerospace Applications: In aerospace and defense, tungsten rods are applied in parts that must endure extreme environmental conditions. They are used as balancing weights, missile components, and radiation shielding materials, benefiting from tungsten’s density and strength.

Manufacturing and Tooling: Tungsten rods are frequently machined into high-performance tools for shaping, cutting, and drilling other metals. Tungsten carbide, an alloy with incredible hardness, is especially common in industrial machining due to its resilience and ability to retain sharpness over long durations, even in challenging environments.

Environmental Applications: The use of tungsten rods has expanded to environmental equipment, such as discharge electrodes in air and water purifiers, due to their durability and conductive properties. This helps in producing reliable and effective systems for removing pollutants and contaminants.

Tungsten rods remain a preferred choice where durability, temperature tolerance, and reliability are paramount. Their applications in such a broad spectrum of fields underline tungsten’s role as a crucial material in modern technology and industry.