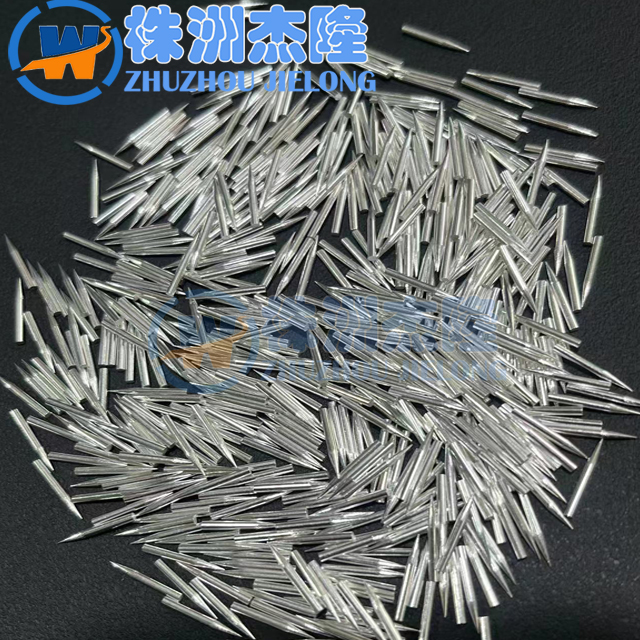

When selecting a suitable electrostatic discharge needle for dust removal or

other applications, consider the following key factors:

1. Material Quality

Tungsten or Tungsten Alloy: Known for high melting points, durability, and excellent discharge performance. Ideal for high-temperature or heavy-duty applications.

Stainless Steel: A cost-effective option, suitable for less demanding environments.

Choose materials resistant to corrosion and wear for longer life.

2. Sharpness and Tip Design

A sharp tip ensures better discharge efficiency. Consider precision-engineered needles for optimal performance.

3. Compatibility

Ensure the discharge needle is compatible with your specific ionization or dust removal system. Confirm dimensions, mounting type, and electrical specifications match your equipment.

4. Durability

Opt for needles that can withstand prolonged usage without significant degradation, especially in industrial environments.

5. Environmental Considerations

If used in humid, corrosive, or high-temperature settings, select materials like tungsten with coatings to enhance resilience.

6. Manufacturer Reliability

Choose reputable manufacturers or suppliers with a track record of quality products. Look for certifications and customer reviews.

7. Cost vs. Performance

Balance price with quality and durability to ensure cost-effectiveness over time.

8. Application-Specific Requirements

For sensitive environments (e.g., electronics manufacturing), use needles with anti-static properties to minimize the risk of contamination.

9. Maintenance Needs

Consider needles that are easy to clean and maintain, ensuring consistent performance over time.

10. Safety Compliance

Ensure the needles meet safety standards for electrostatic discharge systems in your region.

Choosing the right electrostatic discharge needle ensures better performance, increased efficiency, and longer equipment life.