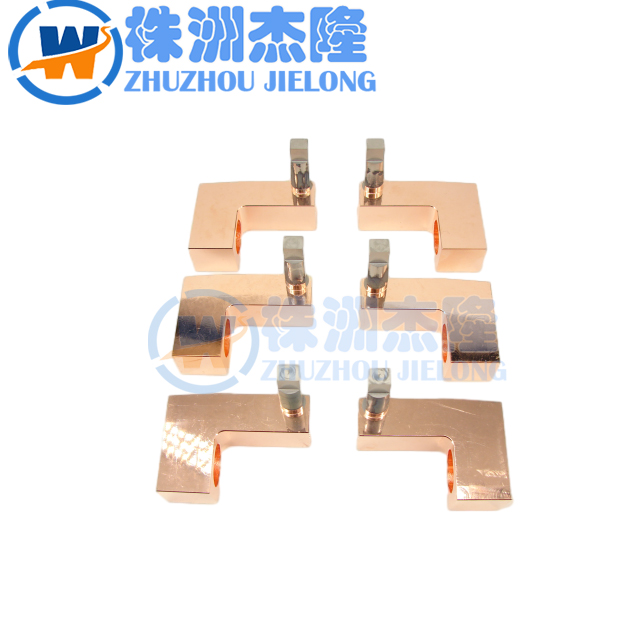

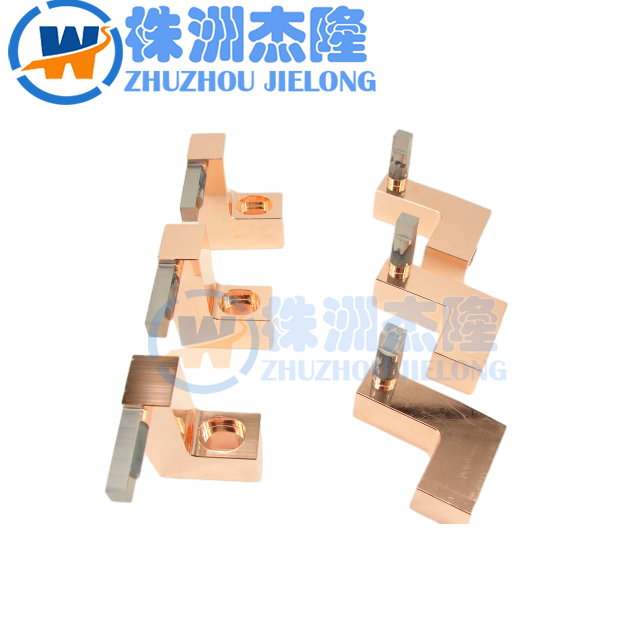

High-Conductivity Tungsten Copper Electrodes for Industrial Use

In the world of industrial manufacturing and welding, the choice of materials can make or break the efficiency and quality of your operations. Tungsten copper electrodes have emerged as a game-changer, particularly in applications requiring high conductivity, durability, and resistance to extreme conditions. Among these, high-conductivity tungsten copper

electrodes stand out as a top choice for industrial use.

What Makes Tungsten Copper Electrodes Unique?

Tungsten copper electrodes are a composite material that combines the best properties of tungsten and copper. Tungsten provides exceptional hardness, high melting points, and excellent wear resistance, while copper offers superior thermal and electrical conductivity. This unique combination makes tungsten copper electrodes ideal for demanding industrial environments, such as arc welding, electrical discharge machining (EDM), and high-temperature applications.

Key Benefits of High-Conductivity Tungsten Copper Electrodes

Superior Electrical and Thermal Conductivity

The high copper content in these electrodes ensures excellent electrical and thermal conductivity, making them perfect for applications that require efficient heat dissipation and minimal energy loss.Exceptional Durability

Tungsten's hardness and resistance to wear ensure that these electrodes can withstand prolonged use in harsh conditions, reducing the need for frequent replacements.High Melting Point

With a melting point exceeding 3,000°C, tungsten copper electrodes are ideal for high-temperature processes, such as plasma arc welding and cutting.Corrosion Resistance

These electrodes are highly resistant to corrosion, making them suitable for use in environments where exposure to chemicals or moisture is a concern.Versatility

High-conductivity tungsten copper electrodes are widely used in industries such as aerospace, automotive, electronics, and heavy machinery, thanks to their adaptability to various applications.

Applications in Industrial Settings

Arc Welding: Their high conductivity and durability make them ideal for creating strong, precise welds in heavy-duty materials.

Electrical Discharge Machining (EDM): The electrodes' ability to maintain shape under extreme heat ensures accurate and efficient machining.

Plasma Cutting: Their high melting point and thermal conductivity allow for clean, precise cuts in thick materials.

Resistance Welding: The electrodes' low electrical resistance ensures consistent performance in high-current applications.

Choosing the Right Tungsten Copper Electrodes

When selecting tungsten copper electrodes for industrial use, consider factors such as the copper-to-tungsten ratio, electrode size, and specific application requirements. Higher copper content generally improves conductivity, while higher tungsten content enhances durability and heat resistance.

Conclusion

High-conductivity tungsten copper electrodes are an indispensable tool in modern industrial manufacturing. Their unique combination of strength, conductivity, and resistance to extreme conditions makes them a reliable choice for a wide range of applications. Whether you're working on precision welding, high-temperature cutting, or heavy-duty machining, these electrodes deliver the performance and longevity your operations demand.

Investing in high-quality tungsten copper electrodes is not just a choice—it's a strategic decision to enhance productivity, reduce downtime, and achieve superior results in your industrial processes.